When exclusivity expresses itself through perfection and quality

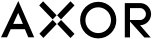

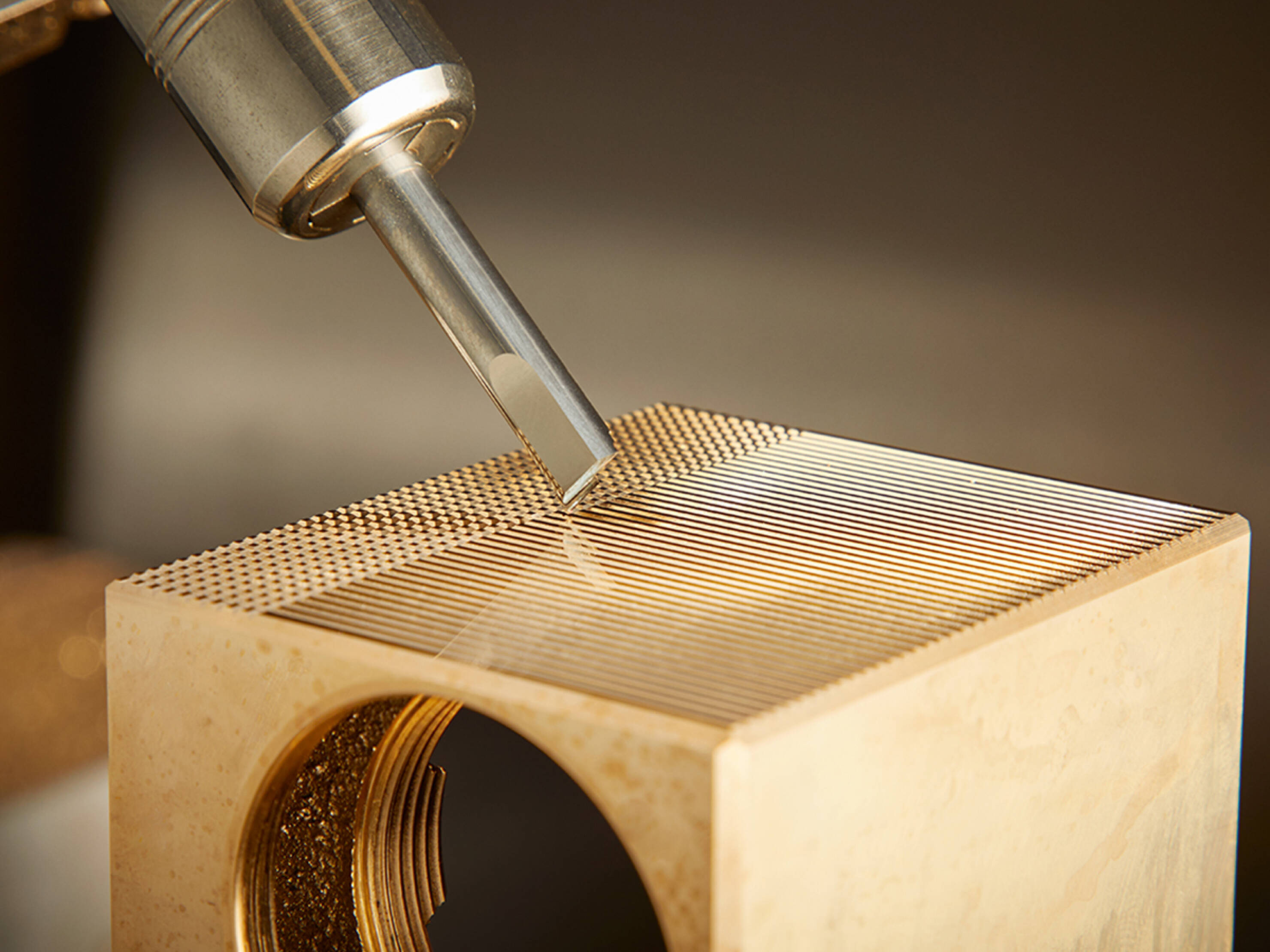

Diamond machines are used in the optics and aerospace industries to achieve the highest precision and surface quality. The experts from the Product Development department at AXOR also rely on machining with a diamond tool to create a surface shine that is second to none, or to mill textures – line by line, down to the micrometer. The result is a jewel that becomes a visual and haptic experience through its brilliance and partial diamond cut: AXOR Edge.

The faucets in this exclusive bathroom collection are one-of-a-kind jewels. With the AXOR Edge, designer Jean-Marie Massaud's aim was to turn an everyday object into a sculpture that evokes emotions with its precise edges, high-gloss surfaces, and refined textures. And like in the jewelery industry, diamond tools are also used for the AXOR Edge. Here, the highest precision, finest details, and most premium materials ensure perfection and quality – and thus exclusivity that is off the beaten track and stands for perfect refinement.